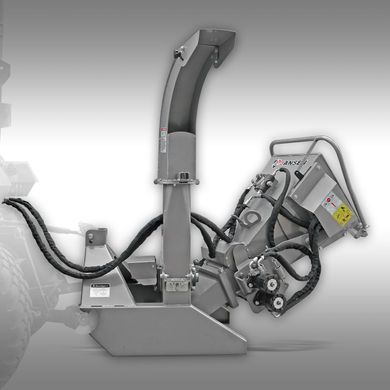

Working with the BX-42RS is a real pleasure thanks to the hydraulic feeding system. In this model, passing, pushing, etc. are a thing of the past; 2 large feed rollers take care of this themselves. The speed of the feed rollers can be adjusted continuously. This is important so that the feeding speed can be adjusted to the diameter of the material being shredded. Smaller diameter material can be fed faster than larger diameter material. If the feeder gets blocked, it can be reversed using the large handle on the feed hopper. In addition, the feed can be turned off using this handle. The unit is powered by the tractor's hydraulic system; a pressurized feed line and a non-pressurized return line are required, or alternatively a double acting controller is required.

We immediately deliver the BX version of shredders, which has double-sided mounting of feed rollers and a reinforced feed hopper. The wood chipper is delivered complete with PTO. There is also a shear pin built into one side of the PTO, which serves as a precaution as a predetermined break point in the event of a jam or overload. This means that even larger tractors with power over 100 HP can be used without problem. The engine power should be at least 25-30 HP. The rotational speed of the unit injector must be 540 rpm. The hopper has an opening of 51 x 51 cm; in the lower part, the opening measures 10.2 x 25.4 cm. Cuttings with a maximum diameter of 10 cm can be shredded. Many competitors list the maximum chopping diameter as a measurement of the bottom of the hopper, but this value is unrealistic and may trigger a safety mechanism in the PTO. Softwood up to 15 cm wide can be chipped, although such diameters are usually processed into firewood rather than wood chips. The BX-42RS has a very solid finish! The strength of the sheet material in the load-bearing area is 10 and 5 mm.

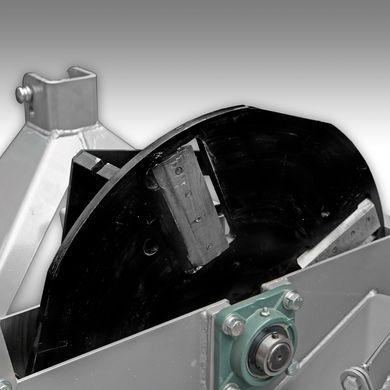

In the case of the hopper and non-load-bearing parts, it is 2 mm. The tank can be easily folded up for transport and secured with a pin. To facilitate folding upwards, the chipper has 2 shock absorbers. The design of the device is very easy to maintain; the flywheel cover can be opened completely by unscrewing just one screw, giving access to the 4 cutting blades. The cutting blades are double-sided, so they can be rotated when necessary. The flywheel has a net mass of 50 kg and is equipped with wings that create extremely strong suction that ultimately ejects the chips from the chute. Thanks to such strong suction, it is virtually impossible to block the shredding unit. The chute is 152 cm high (plus the height of the lower connector) and can be rotated 360 degrees. On request, we can also supply a 50 cm chute extension. This allows you to easily direct the chips onto a tractor trailer or directly into Big Bags. You can also change the throwing angle. The BX-42RS model can throw wood chips at a distance of up to 6 m. The shredder is designed to be mounted on a 3-point suspension system and can be used from Cat. AND.

ATTENTION:

The device is delivered well packed and partially assembled in a steel box. Approximately 1 hour should be allocated for final assembly. Step-by-step assembly instructions and several detailed diagrams are part of the manual included with the chipper.